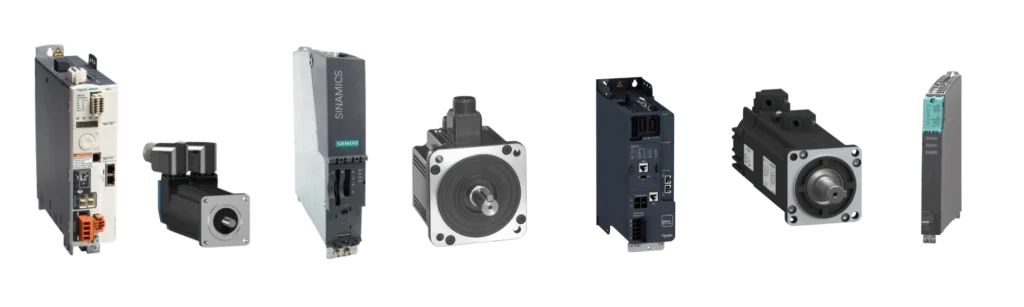

Industrial Servo Drives & Motors | New, Surplus & Obsolete

We stocks hundreds of industrial servo drives and servo motors from Schneider Electric Allen-Bradley, and Siemens —ready to ship the same day from our USA warehouse. We specialize in new, refurbished, and hard-to-find obsolete servo components with complete system matching.

Quick Diagnostics: Identifying Drive vs. Motor vs. Cable Failure

| Component | Physical Symptoms | Common Fault Codes | Immediate Action |

| Servo Drive | Burnt electronics smell, dark HMI display, “Ready” LED off, clicking relays | Overcurrent (OC), Overvoltage (OV), DC Bus Fault | Replace drive or inspect IGBT power module |

| Servo Motor | Grinding/growling noise, excessive vibration, locked/seized shaft, overheating | Overload (OL), Thermal Fault (OH), Phase Loss | Replace motor or check bearings and windings |

| Feedback Cable | Intermittent faults during motion, position loss, erratic behavior | Encoder Error (FE), Communication Loss (Cn), Data Error | Replace shielded feedback cable and check connectors |

Servo Drive vs. VFD: When Do You Need a Servo?

Not every application requires a servo system. Use this comparison to determine the right drive technology for your machinery:

Feature | Servo Drive | VFD (Variable Frequency Drive) |

Control Method | Closed-loop with encoder feedback | Open-loop speed control (or simple encoder) |

Positioning Accuracy | ±0.001° to ±0.01° (sub-millimeter) | No position control |

Response Time | 1-5 milliseconds | 50-200 milliseconds |

Torque at Low Speed | 100% rated torque at zero RPM | Torque drops significantly below 30 Hz |

Speed Regulation | ±0.01% speed accuracy | ±0.5% to ±2% speed accuracy |

Typical Cost | $500 – $15,000+ | $200 – $5,000 |

Best Applications | CNC machining, robotics, packaging registration, pick-and-place | Pumps, fans, conveyors, mixers, general speed control |

When to Choose a Servo:

- Your application requires precise position control

- You need rapid acceleration and deceleration cycles

- Full torque is required at standstill or low speeds

- Repeatability and accuracy are critical (±0.01 mm or better)

- Multi-axis synchronized motion control

When a VFD is Sufficient:

- You only need to vary motor speed

- Positioning accuracy is not required

- Load changes are gradual and predictable

- Cost is the primary consideration

Still not sure? Contact our technical team for application-specific recommendations.

Shop Industrial Servo Drives and Motors — In Stock and Ready to Ship

Our Certifications

What is a Servo Drive? Understanding Motion Control Systems

A servo drive (also called a servo amplifier or servo controller) is the electronic brain that converts low-power command signals from your PLC or motion controller into high-current, variable-frequency AC power to precisely control a servo motor. Together, the drive and motor form a closed-loop feedback system that enables micron-level positioning accuracy that standard AC induction motors cannot achieve.

The Three Components of Every Servo System:

- The Servo Drive (The Controller)

Receives position, velocity, or torque commands from your PLC or CNC controller and amplifies them into high-voltage, high-current signals. Modern drives use pulse-width modulation (PWM) to control motor speed, torque, and position with extreme precision. The drive continuously monitors feedback from the motor and makes real-time adjustments to correct any deviation from the commanded position. - The Servo Motor (The Actuator)

A brushless AC or DC motor engineered for rapid acceleration, deceleration, and precise positioning. Industrial servo motors contain permanent magnet rotors for high torque density and high-resolution feedback devices (encoders or resolvers) mounted directly on the motor shaft. Unlike standard induction motors, servo motors are designed for continuous start-stop cycles and can deliver full rated torque even at zero speed. - The Feedback Device (The Sensor)

An encoder, resolver, or Sin/Cos sensor mounted on the motor shaft continuously reports position, velocity, and sometimes temperature back to the drive. This creates the “closed-loop” control that allows the system to detect and correct position errors in real-time. Common encoder types include incremental TTL, Sin/Cos analog, EnDat digital absolute, and Hiperface DSL single-cable systems.

The Result: Position accuracy of ±0.001° to ±0.01°, velocity regulation within ±0.01%, and response times measured in milliseconds—the performance standard for CNC machining, robotics, and precision packaging equipment.

Voltage Class & Power Rating Quick Reference

Our inventory spans a wide range of power ratings and voltage classes. Use this chart to narrow your search based on your application requirements:

Power Rating Categories:

| Power Range | Typical Applications | Motor Frame Size | Products in Stock |

| 100W – 750W | Small pick-and-place robots, label applicators, small conveyors | 40mm – 80mm flange | Schneider BCH16/BCH2M, Omron R88D-HS |

| 1kW – 3kW | CNC mills (small), packaging machines, palletizers, assembly automation | 100mm – 130mm flange | Schneider LXM26/LXM28, Siemens S120 |

| 4kW – 10kW | CNC machining centers, injection molding, large conveyors, press brakes | 130mm – 180mm flange | Schneider LXM32, Siemens S120, AB Kinetix |

| 15kW – 110kW | Heavy CNC lathes, large robotics, extrusion lines, metal stamping presses | 180mm+ flange | Siemens SINAMICS S120 motor modules |

Voltage Class Options:

200-240V Class (Single or 3-Phase)

- Common in North American facilities with 208V or 230V service

- Ideal for smaller machines and retrofit applications

- Products: Schneider LXM23/26, smaller SINAMICS modules

380-480V Class (3-Phase Only)

- Standard for industrial 3-phase power (460V or 480V)

- Required for motors above 5kW in most applications

- Products: Schneider LXM28/32, Siemens S120, AB Kinetix 6000

Critical: Never attempt to operate a 480V motor on a 230V drive or vice versa. Voltage class mismatch will cause immediate motor failure or fire hazard.

Drive-Motor Pairing Guide by Brand

Replacing a servo component isn’t plug-and-play unless you match the exact specifications. Here’s how to ensure compatibility with the major brands in our inventory:

Schneider Electric Lexium Series

Drive Families:

- LXM23 — Compact, 0.1 to 2 kW, 200-240V single/3-phase

- LXM26 — Mid-range, 0.4 to 4.5 kW, 200-240V or 400-480V 3-phase

- LXM28 — High-performance, 0.75 to 7 kW, 400-480V 3-phase

- LXM32 — Advanced, 0.5 to 15 kW, single or 3-phase with extended diagnostics

Compatible Motor Series:

- BCH16 (Lexium 16D) — Low to mid inertia, 40mm to 100mm flange, 100W to 1.5kW

- BCH2M (Lexium 28) — Mid to high inertia, 40mm to 180mm flange, 100W to 4.5kW

Encoder Compatibility:

- Lexium drives support Sin/Cos 1Vpp, Hiperface, EnDat 2.2, and Resolver feedback

- Most BCH motors ship with Sin/Cos encoders (standard resolution: 2048 to 4096 PPR)

- High-resolution options available with 23-bit absolute encoders

Communication Protocols:

- CANopen, Modbus TCP, EtherCAT (LXM32 only)

- Analog ±10V and Pulse/Direction (all models)

Pairing Rule: Match the LXM drive power rating to the BCH motor power rating. Example: LXM26DU04M3X (400W drive) pairs with BCH16D04330F5C (400W motor).

Siemens SINAMICS S120 System

Drive Components:

- Control Unit (CU320) — 6SL3040-0MA00-0AA1 (required for all systems)

- Single Motor Modules — 6SL3120-1TE series (booksize, internal air cooling)

- 6SL3120-1TE23-0AA3 (30A, 16kW)

- 6SL3120-1TE28-5AA3 (85A, variable power)

- 6SL3120-1TF32-0AA4 (200A, 110kW)

Compatible Motor Series:

- 1FK7 (Simotics S) — High-dynamic servo motors, 0.3 to 45 kW

- 1FT7 (Simotics T) — Torque motors for direct-drive applications

- 1PH8 — High-torque synchronous motors

Encoder Compatibility:

- Siemens motors use Hiperface DSL single-cable feedback (most common)

- Older motors may use TTL incremental or Resolver (check motor nameplate)

- Absolute encoder option available with battery backup

Communication Protocols:

- PROFINET (standard, recommended for new installations)

- PROFIBUS DP (legacy systems)

- EtherNet/IP, EtherCAT (via gateway modules)

Pairing Rule: The motor module current rating must exceed the motor’s rated current. Example: A 1FK7 motor rated at 25A continuous requires a motor module rated for 30A or higher (6SL3120-1TE23-0AA3).

Allen-Bradley Kinetix Series

Drive Families:

- Kinetix 6000 — Modular multi-axis system (discontinued but widely installed)

- Kinetix 5500 — Current-generation EtherNet/IP servo drives

- Kinetix 5700 — Advanced drives with integrated safety and power monitoring

Compatible Motor Series:

- MPL — Low-inertia rotary motors, 0.2 to 13 Nm

- MPM — Medium-inertia motors for general automation

- TL-series — Linear motors for gantry systems

Encoder Compatibility:

- Kinetix drives require Rockwell’s Feedback-Only Encoder (FOE) protocol

- Incremental or absolute encoder options (most use absolute for homing)

- Non-AB motors require encoder conversion or adapter modules

Communication Protocols:

- EtherNet/IP (native, required for multi-axis coordination)

- SERCOS (Kinetix 6000 legacy systems)

Pairing Rule: Allen-Bradley systems are proprietary. Use only AB-branded motors unless you have a verified third-party adapter. Mixing brands without proper configuration will result in communication faults.

Yaskawa Sigma Series

Drive Families:

- SGDM (Sigma-II) — Legacy drives, still widely used

- SGDV (Sigma-5) — Mid-range, standard industrial applications

- SGD7S (Sigma-7S) — High-performance with advanced tuning

Compatible Motor Series:

- SGM — Rotary servo motors with incremental or absolute encoders

- SGMG — Geared servo motors (integrated planetary gearbox)

Encoder Compatibility:

- Incremental encoder (17-bit, 20-bit resolution)

- Absolute encoder with battery backup (EnDat, Yaskawa serial)

Communication Protocols:

- Mechatrolink-III (Yaskawa proprietary)

- EtherCAT, EtherNet/IP (Sigma-7 models)

Pairing Rule: Yaskawa drives and motors are typically sold as matched pairs. Verify encoder type and resolution before mixing components.

Cross-Brand Compatibility Warning

You CANNOT mix brands without severe limitations:

- A Siemens motor will not work on an Allen-Bradley drive (encoder protocol mismatch)

- A Schneider motor on a Yaskawa drive requires custom encoder mapping (not recommended)

- Communication protocols are brand-specific (EtherNet/IP ≠ PROFINET ≠ Mechatrolink)

When to Consider Cross-Brand Pairing:

- Using analog ±10V or pulse/direction control (not fieldbus)

- Motor encoder can be replaced with a compatible type

- You have engineering support to remap encoder signals

Our Recommendation: Always match drive and motor brands for reliability and simplified troubleshooting. If you need to mix brands, contact our technical team for feasibility assessment.

Technical Selection Guide: How to Match Drive to Motor

Replacing a failed servo component requires verifying five critical specifications. Missing even one can result in incompatibility, damage, or safety hazards.

1. Voltage Class Compatibility

200V Class (200-240 VAC)

- Single-phase 230V or 3-phase 208V/230V input

- Common in North American facilities with 208V distribution

- Typical power range: 100W to 5kW

400V Class (380-480 VAC)

- 3-phase 460V or 480V input (North America) or 400V (Europe)

- Required for motors above 5kW in most applications

- Higher voltage = lower current = smaller wire gauge

CRITICAL: Never connect a 480V motor to a 230V drive or vice versa.

- Undervoltage scenario (230V drive, 480V motor) → Motor won’t turn, thermal overload trips

- Overvoltage scenario (480V drive, 230V motor) → Instant winding insulation failure, possible fire

How to Check: Look at the motor nameplate voltage rating and the drive input voltage specification. They must match exactly.

2. Current & Power Rating

The drive’s continuous current rating must meet or exceed the motor’s rated current. Peak current capability should be 150-200% of continuous for acceleration.

Example Calculation:

- Motor nameplate: 3 kW, 6.5A continuous, 19.5A peak (3x multiplier)

- Required drive: Minimum 6.5A continuous, 20A peak recommended

- Suitable drive: Schneider LXM26DU04M3X (7A continuous, 21A peak)

Power Rating Notes:

- A 5kW drive can run a 3kW motor (oversized is fine for future expansion)

- A 3kW drive cannot reliably run a 5kW motor (will trip on overcurrent during acceleration)

- Servo drives are rated in kW or Amps—always verify both specifications

How to Check: Compare motor nameplate current to drive datasheet current ratings. When in doubt, choose the next size larger drive.

3. Feedback Protocol Match

This is where most non-exact replacements fail. The drive and motor encoder must speak the same “language.”

Common Encoder Types:

| Encoder Type | Signal Format | Typical Brands | Resolution |

| Incremental TTL | 5V digital square waves (A, B, Z channels) | Older AB, Fanuc, generic motors | 1000-5000 PPR |

| Sin/Cos 1Vpp | Analog sine/cosine signals | Siemens, Schneider, Lenze | 2048-4096 PPR (interpolated to 20-bit) |

| EnDat 2.2 | Digital absolute encoder protocol | Heidenhain, Siemens, Schneider | 23-bit to 25-bit absolute |

| Hiperface DSL | Single-cable digital feedback | Siemens (proprietary) | 22-bit absolute |

| SSCNET III/H | Mitsubishi serial encoder | Mitsubishi only | 23-bit absolute |

| Resolver | Analog R1/R2 transformer-based | Legacy Fanuc, older Siemens | 12-bit to 16-bit equivalent |

CRITICAL: A Sin/Cos motor will NOT work with a drive expecting TTL signals without an expensive encoder conversion module. You must match encoder protocols exactly.

How to Check:

- Look at the motor feedback connector (how many pins?)

- Check motor datasheet for encoder type

- Verify drive supports that exact encoder protocol

- If replacing motor only, match encoder type to existing drive

4. Communication Protocol

Servo drives connect to PLCs and motion controllers via industrial networks. The protocol must match your existing automation infrastructure.

Common Protocols:

| Protocol | Typical Brands | Speed | Topology | Best For |

| EtherNet/IP | Allen-Bradley, Yaskawa, Omron | 100 Mbps | Star (switched Ethernet) | Rockwell Automation systems |

| PROFINET | Siemens, Lenze, Bosch Rexroth | 100 Mbps | Star (switched Ethernet) | Siemens PLC ecosystems |

| EtherCAT | Beckhoff, Delta, Yaskawa Sigma-7 | 100 Mbps | Daisy-chain (ring) | High-speed multi-axis coordination |

| SERCOS III | Bosch Rexroth, Kollmorgen | 100 Mbps | Ring topology | Legacy high-performance systems |

| CANopen | Schneider, Lenze, generic drives | 1 Mbps | Multi-drop bus | Simple automation, cost-sensitive |

| Analog ±10V / Pulse-Train | All brands (universal fallback) | N/A | Point-to-point wiring | Standalone machines, no PLC integration |

Legacy Note: Older Kinetix 6000 systems use SERCOS I/II, which is incompatible with modern SERCOS III drives.

How to Check: Identify your PLC brand and the existing servo communication network. If you’re unsure, contact our technical team with your PLC model number.

5. Physical Mounting & Shaft Dimensions

Even if electrical specs match perfectly, the motor must physically fit your machine’s mounting bracket and couple to the gearbox or load.

Motor Frame Sizes (IEC Standard):

- 40mm flange — Micro servos, 100W to 400W

- 60mm flange — Small servos, 200W to 750W

- 80mm flange — Compact servos, 400W to 1.5kW

- 100mm flange — Mid-range servos, 750W to 2kW

- 130mm flange — Standard servos, 1kW to 5kW

- 180mm flange — Large servos, 3kW to 15kW

Shaft Dimensions:

- Diameter: 8mm, 11mm, 14mm, 19mm, 22mm, 24mm, 28mm (common sizes)

- Key slot: Check keyway dimensions (ISO or DIN standard)

- Shaft length: Ensure sufficient length for coupling and encoder mounting

NEMA vs. IEC Flanges:

- NEMA (North America): Inch-based bolt patterns (NEMA 23, 34, 42)

- IEC (International): Metric bolt patterns (60mm, 80mm, 130mm)

- Not interchangeable — bolt holes won’t align

How to Check:

- Measure flange bolt hole spacing (center-to-center)

- Measure shaft diameter with calipers

- Verify shaft length from flange face to shaft end

- Check motor cable connector type (some are brand-specific)

Can’t find an exact physical match? Contact us—we can source adapter plates, custom couplings, or equivalent motors with the correct mounting.

Troubleshooting Fault Codes: OC, FE, OV, OL, BAT

When a servo system fails, the drive typically displays a fault code on its LED or HMI. Use this table to identify the root cause and determine which component needs replacement.

| Fault Type | Display Code Examples | Most Likely Cause | Component to Inspect | Diagnostic Steps |

| Overcurrent (OC) | AL-12, E12, OF1, OC001 | Short circuit in motor windings, drive power module failure, mechanical jam | Motor phase-to-phase resistance, Drive IGBT module | 1. Disconnect motor cables<br>2. Measure motor winding resistance (should be 0.5-50Ω, balanced)<br>3. If motor OK, replace drive |

| Feedback Error (FE) | AL-37, E86, EnF, FE001 | Damaged feedback cable, dirty encoder glass, encoder power loss | Encoder assembly, Feedback cable shielding | 1. Inspect cable for cuts or pinch damage<br>2. Check connector pins for corrosion<br>3. Measure encoder power voltage (5V or 12V)<br>4. Replace cable before replacing motor |

| Overvoltage (OV) | AL-10, E10, OV1, OV002 | Regenerative energy during deceleration, failed braking resistor | External braking resistor, DC bus capacitors | 1. Measure braking resistor with multimeter (should be 20-100Ω)<br>2. Check for burn marks or open circuit<br>3. Verify resistor wattage matches application |

| Overload (OL) | AL-51, E51, OL2, OL003 | Motor undersized for load, mechanical binding, prolonged high-torque operation | Motor thermal switch, Mechanical coupling/gearbox | 1. Check if load is jammed or seized<br>2. Verify motor power rating matches application<br>3. Inspect coupling for misalignment |

| Encoder Battery (BAT) | BAT, bAt, A90, BE001 | Absolute encoder backup battery depleted (CR2032 or similar) | Motor encoder battery compartment | 1. Locate battery on motor (usually under connector cover)<br>2. Replace with CR2032 lithium battery<br>3. Re-home motor after battery replacement |

| Communication Loss (Cn) | AL-16, E16, Cn, COM01 | Network cable failure, incorrect IP address, protocol mismatch | EtherNet/IP cable, Network switch, Drive IP settings | 1. Check Ethernet cable for damage<br>2. Verify drive IP address matches PLC configuration<br>3. Confirm correct communication protocol selected |

Additional Fault Code Resources:

Brand-Specific Fault Code Manuals:

- Allen-Bradley Kinetix: Search “Kinetix 6000 fault codes” + drive model

- Siemens SINAMICS: Fault code list in SINAMICS S120 manual (starts with F or A)

- Schneider Lexium: LXM error codes documented in user manual (Exx format)

- Yaskawa Sigma: Alarm code list in SGDM/SGD7 technical manual (Axx format)

Pro Tip: Before replacing expensive drives or motors, always check the feedback cable first. We estimate that 90% of “encoder error” faults are caused by damaged cables, not failed encoders. A $50 cable replacement can save you from a $2,000 motor purchase.

Common Servo Applications

Servo drives and motors are essential in industries where precision motion control, rapid acceleration, and repeatable positioning are critical. Here are the most common applications we support:

CNC Machining & Metal Fabrication

Typical Equipment:

- Multi-axis CNC mills, lathes, and machining centers

- Laser cutting and plasma cutting tables

- Turret punch presses and press brakes

Requirements:

- High-torque motors for heavy cutting forces

- Encoder accuracy of ±0.01mm or better

- Rigid couplings to minimize backlash

- Coordinated multi-axis motion (3 to 5+ axes)

Recommended Products: Siemens SINAMICS S120 (5-30kW), Fanuc Alpha series, Allen-Bradley Kinetix 6000

Packaging & Labeling

Typical Equipment:

- Flow wrappers and form-fill-seal machines

- Label applicators and print-apply systems

- Cartoning machines and case packers

- Flying cutoff and rotary knife systems

Requirements:

- Fast acceleration/deceleration (0 to 3000 RPM in <100ms)

- Electronic gearing and cam profiles

- Registration inputs for product tracking

- Washdown-rated motors for food packaging (IP65/IP69K)

Recommended Products: Schneider Lexium LXM26/LXM28, Yaskawa Sigma-7, Omron R88D series

Robotics & Material Handling

Typical Equipment:

- Industrial robot arms (6-axis articulated)

- SCARA robots for assembly automation

- Gantry systems and Cartesian robots

- Palletizers and depalletizers

Requirements:

- Low-inertia motors for fast response

- Coordinated multi-axis motion control

- Safe torque-off (STO) for machine safety compliance

- High overload capacity for dynamic loads

Recommended Products: Allen-Bradley MPL/MPM motors, Schneider BCH series, Yaskawa SGM motors

Printing & Converting

Typical Equipment:

- Flexographic and offset printing presses

- Web tension control systems

- Rotary die cutting and slitting machines

- Laminating and coating lines

Requirements:

- Electronic line shafting (virtual master axis)

- S-curve motion profiles for smooth acceleration

- Torque mode control for tension regulation

- High-resolution encoders for color registration (±0.05mm)

Recommended Products: Schneider Lexium LXM32, Siemens SINAMICS S120, Bosch Rexroth IndraDrive

Food & Beverage Production

Typical Equipment:

- Conveyor systems and sortation lines

- Filling machines and dosing systems

- Bottling lines and capping machines

- Mixing and blending equipment

Requirements:

- Washdown-rated motors (IP69K for high-pressure cleaning)

- FDA-compliant materials (stainless steel, food-grade seals)

- Sanitary design (smooth surfaces, no crevices)

- Resistance to chemicals and temperature extremes

Recommended Products: Schneider BCH washdown motors, Lenze m550 series, stainless steel servo options

Semiconductor & Electronics Manufacturing

Typical Equipment:

- Wafer handling robots

- Pick-and-place machines for SMT assembly

- Wire bonding and die attach equipment

- PCB inspection and testing systems

Requirements:

- Ultra-low vibration (sub-micron repeatability)

- Cleanroom compatibility (Class 10 to Class 1000)

- High-resolution encoders (23-bit absolute or better)

- Smooth motion profiles to prevent component damage

Recommended Products: Yaskawa Sigma-7S, Siemens 1FK7 high-dynamic motors, Kollmorgen AKM series

Product Condition Guide: New vs. NOB vs. Refurbished

We offer servo drives and motors in multiple conditions to fit your budget and timeline. Here’s how to choose the right option:

| Condition | Description | Typical Savings vs. New | Warranty | Best For |

| New (Factory Sealed) | Original manufacturer packaging with unbroken seals, eligible for OEM warranty registration | 0% (List Price) | 2-year Equip Industrial + OEM warranty eligibility | Critical production lines, OEM compliance required, warranty transfer needed |

| New-Open-Box (NOB) | Never installed or energized, packaging opened for inspection or testing, no signs of use | 20-30% savings | 2-year Equip Industrial warranty | Cost-conscious buyers, spare inventory, backup components |

| Refurbished/Tested | Previously in service, fully disassembled, cleaned, tested per our 12-point protocol, may show cosmetic wear | 40-60% savings | 2-year Equip Industrial warranty | Legacy equipment, EOL component replacement, budget-limited projects |

| Repair Exchange | Customer sends failed unit, we repair and return or exchange for tested equivalent unit | 60-75% savings | 1-year warranty on repaired unit | Predictable failures (capacitors, fans), fast turnaround with core credit |

What’s Included with Every Condition:

12-Point Testing — All units (including New-Open-Box) undergo our certification process

Load Testing — Drives tested under actual motor load, not just “power-on” bench tests

Parameter Reset — Memory cleared to factory defaults for plug-and-play installation

Same-Day Shipping — Orders by 3:00 PM EST ship the same day, regardless of condition

Technical Support — Direct access to application engineers for installation assistance

How to Decide:

Choose NEW if:

- Your insurance or warranty requires OEM-certified components

- You need full manufacturer warranty for warranty chain compliance

- Budget is not the primary constraint

Choose NEW-OPEN-BOX if:

- You want like-new performance at a discount

- The component is for backup/spare inventory

- You trust third-party testing (our 12-point protocol)

Choose REFURBISHED if:

- You’re replacing an obsolete (EOL) component where new is unavailable

- Cost savings are critical (40-60% less than new)

- You need a proven solution (our refurbs are load-tested, not just cosmetically cleaned)

Our 12-Point Servo System Certification Process

Unlike surplus dealers who simply “power on” a drive to verify it lights up, we test every servo component as a complete system under real-world load conditions. Here’s our comprehensive quality assurance process:

Visual & Mechanical Inspection

- Visual Inspection

Checking motor shafts for play and runout (±0.002″ tolerance), inspecting drive circuit boards for capacitor leakage, burn marks, or corrosion, and verifying all connector pins for damage or bent contacts. - Megger Testing

High-voltage insulation testing of motor windings using a 500V DC megohmmeter. Winding insulation resistance must exceed 100 MΩ to pass. This test identifies insulation breakdown before it causes catastrophic failure in service. - Ultrasonic Cleaning

Removing carbon dust, oil residue, and contamination from internal components using ultrasonic cleaning baths. Drive circuit boards and motor encoder assemblies are cleaned to prevent future shorts or communication errors.

Component Replacement & Alignment

- Component Replacement

Proactive replacement of aging electrolytic capacitors (typically every 5-7 years) and cooling fans. DC bus capacitors are tested for ESR (Equivalent Series Resistance) and replaced if degraded beyond 120% of original specification. - Encoder Alignment

Verifying the electronic commutation alignment of the motor encoder. Encoder A/B phase offset is checked with an oscilloscope to ensure proper 90° electrical phase relationship. Z-index (homing) signal is verified for proper alignment.

Load & Performance Testing

- Load Testing

Running the drive/motor pair at 100% rated torque on a dynamometer test bench. The system is operated through full acceleration, constant velocity, and deceleration cycles to verify torque production and thermal performance. - Vibration Analysis

Ensuring motor bearings meet OEM specifications using vibration spectrum analysis. Bearings are tested for frequency peaks indicating wear, misalignment, or contamination. Motors exceeding 2.5 mm/s RMS vibration are rejected or re-serviced. - Thermal Imaging

Monitoring for hot spots during long-duration “burn-in” runs using infrared thermal cameras. Drives and motors are operated at 80-100% load for 30-60 minutes while monitoring temperature rise. Any component exceeding rated temperature limits is flagged for further inspection.

Communication & Safety Verification

- Communication Verification

Testing fieldbus communication ports (EtherNet/IP, PROFINET, EtherCAT, CANopen) to ensure proper handshake and data exchange. Network parameters are verified using protocol analyzers to confirm error-free communication. - Firmware Matching

Ensuring the drive firmware revision matches your system requirements. Older firmware versions are available for legacy systems, while the latest firmware is installed for new applications (unless otherwise requested). - Parameter Reset

Wiping old application data and resetting parameters to factory defaults for a “Plug-and-Play” experience. Custom parameter files can be loaded if you provide your existing drive backup file.

Final Preparation

- Custom Packaging

Anti-static bags for circuit boards, foam-in-place protection for heavy motors, and impact-resistant cartons for shipping. Every component is serialized with a test report documenting all 12 inspection points.

📄 Documentation Included: Each tested unit ships with a serialized test report showing insulation resistance readings, vibration data, and thermal imaging results. This documentation is critical for ISO 9001 compliance and warranty claims.

Managing Obsolete/EOL Servo Drives: Your Lifeline

When Siemens discontinues the 6SN1123 series, Allen-Bradley phases out Kinetix 6000 drives, or Fanuc declares Alpha motors “end-of-life,” OEMs push you toward a six-figure retrofit. We specialize in keeping legacy systems running for another decade.

Why Replace an Entire Production Line When You Can Replace One Drive?

The OEM Retrofit Reality:

- New Siemens S210 drive + motor: $3,500 – $8,000 per axis

- System integration and commissioning: $15,000 – $50,000 (engineering, programming, testing)

- Production downtime during retrofit: $10,000 – $100,000+ per day (depending on facility)

- Training for maintenance staff: $5,000 – $15,000 (new drive platform)

- Total cost for 6-axis machine retrofit: $75,000 – $250,000

The Equip Industrial Solution:

- Refurbished exact-match drive: $800 – $2,500 per axis

- Installation time: 2-4 hours (plug-and-play with existing parameters)

- Downtime cost: Minimal (same-day or overnight shipping available)

- Training required: Zero (same drive model, same programming)

- Total cost for 6-axis machine repair: $5,000 – $15,000

Return on Investment:

By sourcing obsolete components instead of retrofitting, you save 85-95% of total project costs and eliminate weeks or months of downtime. Your existing PLC programs, HMI screens, and operator training remain valid.

We Stock Hard-to-Find Legacy Components:

Baldor (Pre-ABB Acquisition)

- BSM series servo motors (50-frame to 190-frame)

- MicroFlex e100 drives

- NextMove controllers

Indramat (Bosch Rexroth Legacy)

- TDM, TVM, DDS AC servo drives

- MAC, MDD, MKD permanent magnet motors

- DKC, DKS digital drive controllers

Reliance Electric (Pre-Rockwell)

- AutoMax distributed I/O and motion controllers

- Electro-Craft servo drives and motors

Bosch Rexroth IndraDrive C (Pre-2015)

- HCS02/03 compact drives

- IndraDyn H synchronous motors

Kollmorgen (Legacy Models)

- Servostar 300/400/600 analog servo drives

- Goldline and AKD legacy motor series

Fanuc (Discontinued Alpha Series)

- A06B-6079, A06B-6088, A06B-6096 servo amplifiers

- Alpha-i servo motors with Pulse Coder feedback

Mitsubishi (Legacy Melservo)

- MR-J2S, MR-J3 servo amplifiers (pre-J4 generation)

- HC-KFS, HC-SFS servo motors

Have an Obsolete Part Number?

Our technical team maintains cross-reference databases for over 50,000 obsolete servo components. We can:

✅ Source exact replacements from our warehouse or supplier network

✅ Cross-reference to current equivalents when exact matches aren’t available

✅ Verify compatibility before shipping (encoder type, voltage class, firmware)

✅ Provide parameter files for newer drives configured to replace older models

Call us at [Phone Number] or email [Email Address] with your part number. We’ll respond within 4 hours with availability and pricing.

Case Study: 48-Hour Emergency Servo Replacement

Real-world examples of how Equip Industrial helped facilities avoid catastrophic downtime:

Case Study #1: CNC Machine Shop Saves $180,000 with Obsolete Drive Replacement

Industry: Precision CNC Machining

Equipment: 5-axis Makino machining center (2008)

Failure: Allen-Bradley Kinetix 6000 servo drive (2094-BC07-M05) catastrophic failure—IGBT module shorted

The Challenge:

The customer’s primary contract manufacturer for aerospace components had a critical production order due in 72 hours. The Kinetix 6000 series was discontinued in 2018, and Allen-Bradley quoted 16-week lead time for a Kinetix 5700 retrofit (new drive series). The retrofit would require:

- Replacing all 5 servo drives ($28,000 in hardware)

- Re-programming the PLC and motion controller ($35,000 engineering)

- Re-tuning all servo axes ($15,000 commissioning)

- 2 weeks of downtime ($120,000 in lost production)

Total retrofit cost: $198,000 + 2 weeks downtime

Our Solution:

We located a refurbished Kinetix 6000 drive (2094-BC07-M05) in our inventory, tested it with a compatible motor, and shipped it via overnight courier within 6 hours of the customer’s call.

Results:

- Cost: $1,850 (refurbished drive + overnight shipping)

- Installation time: 3 hours (direct plug-in replacement)

- Downtime: 8 hours (failure to machine back online)

- Total savings: $196,000 vs. OEM retrofit quote

Customer Testimonial:

“We were facing a catastrophic loss of our largest customer due to delivery failure. Equip Industrial not only found the exact obsolete drive we needed, but had it on our shop floor before the end of the next business day. The drive installed perfectly with our existing parameters, and we made our delivery deadline. This company literally saved our business.” — Maintenance Manager, precision aerospace machining

Case Study #2: Packaging Line Back Online in 24 Hours

Industry: Food & Beverage Packaging

Equipment: High-speed flow wrapper (150 packs/minute)

Failure: Yaskawa Sigma-II servo motor encoder failure—”Encoder Communication Error A.86″

The Challenge:

A national snack food manufacturer’s packaging line went down during peak production season. The Sigma-II series (SGDM drives, SGM motors) was discontinued in favor of Sigma-7. Yaskawa quoted:

- New Sigma-7 drive + motor: $6,200

- Mechanical adapter plate (different flange size): $850

- Re-tuning and commissioning: $3,500

- Lead time: 6-8 weeks

- Estimated downtime cost: $45,000/day × 42 days = $1,890,000

Our Solution:

We had a refurbished SGM servo motor with the exact encoder type in stock. We expedited testing (encoder alignment verification, megger test, vibration analysis) and shipped same-day via next-flight-out air freight.

Results:

- Cost: $1,275 (refurbished motor + expedited shipping)

- Installation time: 2 hours (direct bolt-in replacement)

- Downtime: 1 day (failure to production restart)

- Total savings: $8,775 in parts + $1,845,000 in avoided downtime

Customer Testimonial:

“We called Equip Industrial at 10 AM on a Thursday with a down line. By 8 AM Friday, we had a replacement motor installed and were back to full production. The 2-year warranty gave us confidence, and the motor has been running flawlessly for 18 months now.” — Plant Engineer, food packaging facility

Case Study #3: Siemens SINAMICS S120 Module Replacement Prevents $2.1M Loss

Industry: Automotive Stamping

Equipment: 8-axis transfer press servo system

Failure: Siemens SINAMICS S120 motor module (6SL3120-1TE23-0AA3) DC bus capacitor failure—”Overvoltage Fault F30005″

The Challenge:

An automotive Tier 1 supplier’s 800-ton transfer press failed during a critical production run for a new vehicle launch. Siemens quoted:

- New motor module: $12,500

- Lead time: 22 weeks (global semiconductor shortage)

- Contract penalties for late delivery: $100,000/week

- Estimated total impact: $2,200,000

The customer considered flying in a Siemens field service engineer to attempt repair ($15,000 + 1-week lead time), but no guarantee of success.

Our Solution:

We located a refurbished 6SL3120-1TE23-0AA3 motor module that had undergone our 12-point testing including DC bus capacitor ESR measurement and replacement. We coordinated with the customer’s maintenance team to have our technician on-site for installation support.

Results:

- Cost: $4,200 (refurbished module + on-site installation support)

- Installation time: 4 hours (module replacement + parameter verification)

- Downtime: 18 hours (failure to production restart)

- Total savings: $2,195,800 in avoided contract penalties

Customer Testimonial:

“When Siemens told us 22 weeks, we thought we were finished. Equip Industrial not only had the exact module in stock, but sent a technician to our facility to ensure proper installation. The module came with full test documentation showing capacitor ESR values and thermal imaging—proof it was truly tested, not just pulled off a shelf. We’ve since made Equip Industrial our first call for any Siemens obsolete parts.” — Maintenance Director, automotive stamping plant

What our customers think.

★★★★★

8 days ago

Ordered a Schneider Electric Servo Drive; it arrived on time and worked perfectly. Accurate specs made installation easy. Highly recommend!

★★★★★

13 days ago

Bought a Siemens HVAC Actuator; it fit perfectly and worked as described. Great support and competitive pricing. Very happy!

★★★★★

20 days ago

The Oval Ultra Mass Flow Meter works exceptionally well. Detailed specs and warranty made this a great purchase!

★★★★★

29 days ago

The Allen-Bradley Smart Motor Controller worked perfectly, improving efficiency. Fast delivery and great quality!

FAQs: AC Servo Drives

What is the lifespan of your AC servo drives, and how do they compare to competitors' products?

Our AC servo drives are designed to last for many years under standard operating conditions. We ensure longevity by partnering with trusted manufacturers and rigorously testing each unit for quality. Compared to competitors, our drives feature advanced energy efficiency and durability, significantly reducing the frequency of replacements and maintenance costs. By choosing us, you’re investing in a long-term, reliable solution that minimizes downtime and improves operational efficiency.

How do I know if your AC servo drives will be compatible with my existing system?

Compatibility is key to achieving smooth integration. Our team of experts will help assess your current system’s specifications to ensure that the AC servo drive you choose integrates perfectly with your existing machinery. We provide detailed technical support, including compatibility checks and custom configuration advice, to ensure a seamless transition. This minimizes the risk of system inefficiencies and costly compatibility issues.

Do you offer support for integrating used AC servo drives into complex automation systems?

Yes, we specialize in helping clients integrate both new and used AC servo drives into complex automation systems. Our used drives are carefully inspected, tested, and certified to ensure they meet high-performance standards. Our technical support team is available to assist with system integration, troubleshooting, and optimizing performance. Whether you’re upgrading an existing system or retrofitting older machines, we provide expert guidance for a smooth implementation.

What energy efficiency benefits can I expect from your AC servo drives?

Our AC servo drives are designed with energy efficiency in mind, reducing your overall operational costs. Compared to traditional drives, our units offer optimized performance that adjusts power output based on load requirements, preventing excess energy consumption. You’ll see significant savings on electricity bills while improving the overall efficiency of your machinery. This makes our drives an excellent choice for companies looking to reduce their environmental impact and operational costs.

What warranties or guarantees do you offer with your AC servo drives?

We offer a comprehensive warranty on all of our new and used AC servo drives. For new models, we provide a standard manufacturer warranty, typically ranging from 1 to 3 years, depending on the product. For used units, we offer a warranty period of up to 12 months, ensuring that you have peace of mind when purchasing. In addition, we offer a 30-day return policy, so if you’re not fully satisfied with your purchase, you can return it hassle-free.

How do your AC servo drives help reduce downtime and improve overall system reliability?

Our AC servo drives are built with high reliability and low failure rates, ensuring minimal downtime. The drives are equipped with advanced diagnostic features that detect potential issues before they become serious problems, allowing you to address them proactively. In addition, we offer extensive after-sales support, including remote troubleshooting and on-site consultations if needed. This combination of high-quality products and expert support ensures that your systems stay running smoothly, reducing costly interruptions and boosting your overall operational efficiency.

Let’s Take Your Business to the Next Level with Reliable AC Servo Drives

Choose high-performance solutions that work as hard as you do.