As industrial automation continues to evolve, 2025 promises a new wave of innovation, transforming how businesses operate, enhance efficiency, and ensure reliability. For companies specializing in hardware solutions, like Equip Industrial, understanding these trends is critical to aligning offerings with the future needs of the market. This blog delves into the key trends shaping industrial automation in 2025, highlighting opportunities for businesses invested in advanced hardware solutions.

Trend-1:

Increased Integration of AI in Hardware System

Artificial intelligence (AI) is no longer confined to software solutions. In 2025, its integration into industrial hardware will revolutionize the performance of servo drives, motion controllers, and protection relays. AI-enabled hardware can self-optimize for specific applications, predict maintenance needs, and improve overall operational efficiency.

For example:

- AC Servo Drives with AI integration will feature real-time adjustments to achieve better motion control precision, reducing downtime.

- Protection Relays equipped with AI capabilities will enhance fault detection and prevent system-wide failures.

AI-driven hardware empowers industries to move beyond reactive approaches, leveraging predictive analytics to minimize risks and maximize uptime.

Trend-2:

Edge Computing in Industrial Automation

Edge computing is rapidly gaining traction in industrial automation, driven by the need for real-time data processing at the source. In 2025, industrial hardware equipped with edge computing capabilities will enable manufacturers to process critical data locally, reducing latency and ensuring faster decision-making.

Hardware Applications:

- Motion Controllers with edge computing can process commands locally, enabling ultra-fast response times in precision manufacturing.

- Flow Meters with edge computing capabilities allow industries to analyze flow data on-site, ensuring accuracy without relying on cloud connectivity.

The adoption of edge computing will improve efficiency across sectors like automotive, aerospace, and energy, where milliseconds can make a difference in performance.

Trend-3:

Focus on Energy Efficiency and Sustainability

As sustainability becomes a priority, industries are demanding energy-efficient hardware solutions. In 2025, hardware manufacturers must align their offerings with these demands, developing equipment that minimizes energy consumption while maximizing performance.

Examples of Energy-Efficient Hardware:

- Smart Motor Controllers that optimize power usage during startup and operation.

- Pressure Transmitters designed to maintain high accuracy with reduced energy requirements.

Industries are also shifting toward hardware that supports renewable energy integration, such as circuit breakers and relays designed for solar and wind power systems. By prioritizing energy-efficient products, businesses can stay ahead of the competition while contributing to sustainability goals.

Trend-4:

Interoperability and Open Standards

The need for seamless integration across diverse systems is driving the adoption of interoperable hardware in 2025. Industrial automation increasingly relies on hardware that can communicate across platforms, regardless of the manufacturer.

Key Benefits of Interoperability:

- Simplifies upgrades and retrofits in existing systems.

- Reduces downtime during hardware integration.

- Enhances compatibility with emerging Industry 4.0 technologies.

Hardware like HVAC Controllers, servo drives, and motion controllers designed with open communication standards (e.g., OPC UA, Modbus, Ethernet/IP) will see increased demand as industries aim for seamless operations across devices.

Trend-5:

Advanced Diagnostics and Predictive Maintenance

In 2025, the industrial sector will increasingly rely on hardware with built-in diagnostic capabilities to identify potential issues before they escalate. Predictive maintenance, powered by advanced sensors and analytics, is becoming a standard feature in many industrial devices.

Examples of Diagnostic-Ready Hardware:

- Protection Relays capable of real-time monitoring for electrical faults.

- Precision Flow Meters with sensors to detect clogging or wear in fluid systems.

This shift toward predictive maintenance reduces unplanned downtime, lowers repair costs, and ensures optimal system performance. Industrial businesses that invest in such hardware will gain a competitive edge by improving reliability and efficiency.

Trend-6:

Customization for Industry-Specific Applications

One-size-fits-all solutions are becoming obsolete as industries demand tailored hardware designed for specific applications. In 2025, manufacturers are prioritizing modular and customizable hardware to meet unique industry requirements.

Industry-Specific Trends:

- The automotive industry will require advanced motion controllers for high-speed robotics.

- The oil and gas sector will demand ruggedized pressure transmitters capable of withstanding extreme conditions.

- The pharmaceutical industry will need highly accurate flow meters for precise fluid handling.

Offering customizable hardware solutions allows businesses to address the diverse needs of their clients effectively, driving customer satisfaction and loyalty.

Trend-7:

Resilience Against Cybersecurity Threats

As industrial automation becomes more connected, cybersecurity concerns are at the forefront. In 2025, robust hardware solutions will incorporate advanced security features to protect against cyber threats targeting industrial control systems.

Cybersecure Hardware Examples:

- Circuit Breakers with embedded encryption to safeguard electrical systems.

- HVAC Controllers with secure communication protocols to prevent unauthorized access.

Industries are looking for hardware that not only performs efficiently but also protects their operations from potential cyberattacks, making cybersecurity a non-negotiable aspect of hardware design.

Trend-8:

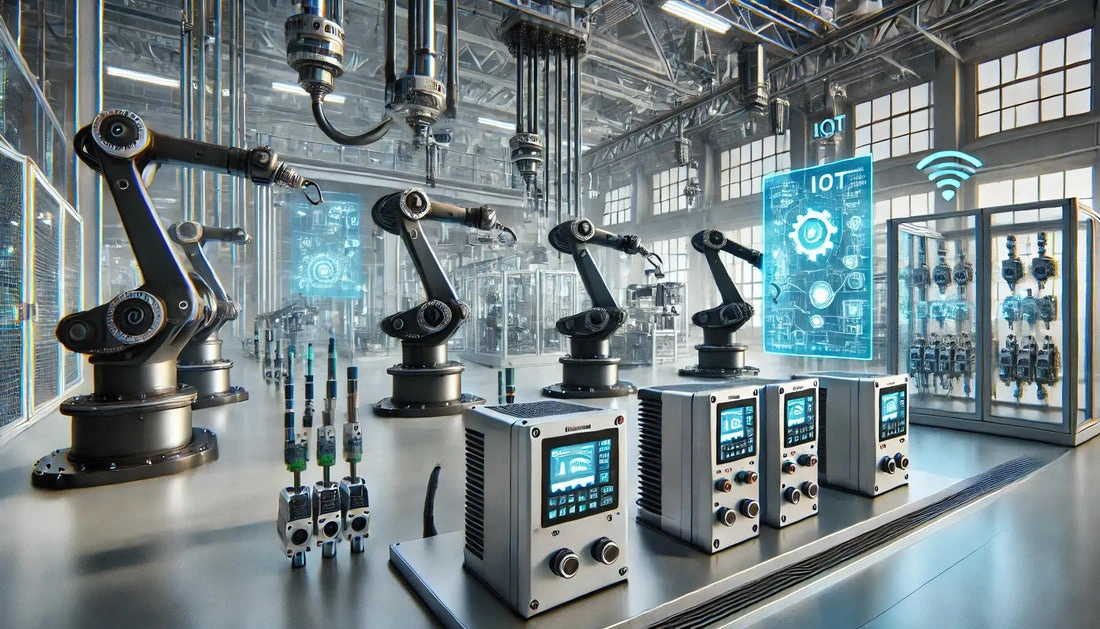

Adoption of IoT-Enabled Devices

The Internet of Things (IoT) is expanding its footprint in industrial automation, enabling remote monitoring and control of hardware systems. In 2025, IoT-enabled devices will dominate the market, offering unparalleled connectivity and insights.

IoT-Enabled Hardware Applications:

- Smart Flow Meters providing real-time data on fluid movement, accessible via mobile devices.

- Servo Drives with IoT capabilities that allow remote adjustments and diagnostics.

IoT integration enhances operational visibility, enabling industries to make data-driven decisions, optimize performance, and reduce costs.

Trend-9:

Automation in Climate Control Systems

With rising energy costs and environmental concerns, industries are investing in automated climate control systems. In 2025, HVAC Controllers and Actuators will play a crucial role in maintaining optimal environmental conditions while minimizing energy use.

Emerging Features in HVAC Hardware:

- Adaptive algorithms for precise temperature and humidity control.

- Compatibility with smart building systems for integrated operation.

Automated climate control systems are particularly critical for industries like food processing, pharmaceuticals, and electronics, where maintaining specific environmental conditions is essential.

Trend-10:

Retrofits and Upgrades for Legacy Systems

The cost of replacing entire industrial systems can be prohibitive, driving the demand for hardware designed to retrofit and upgrade legacy systems. In 2025, retrofitting solutions will gain traction, allowing industries to modernize operations without the need for complete overhauls.

Popular Retrofit Solutions:

- Servo Drives that integrate with older motion control systems.

- Protection Relays that provide modern features while working with existing setups.

This trend ensures industries can adopt cutting-edge technology without disrupting their operations or exceeding budgets.

Conclusion

The future of industrial automation in 2025 is defined by innovation, sustainability, and adaptability. For businesses like Equip Industrial that specialize in hardware solutions, staying ahead of these trends is crucial to meeting the evolving demands of the market.

Equip Industrial is committed to helping businesses navigate these trends with a wide range of high-quality, reliable hardware designed to enhance industrial automation. Whether you’re looking for servo drives, motion controllers, or HVAC controllers, our solutions are built to meet the challenges of 2025 and beyond.